Engineering plastic production

Time:

Nov 12,2024

In recent years, the production of engineering plastics has been on the rise, with demand skyrocketing in various industries such as automotive, electronics, and construction.

In recent years, the production of engineering plastics has been on the rise, with demand skyrocketing in various industries such as automotive, electronics, and construction. This surge in demand can be attributed to the unique properties of engineering plastics, which make them ideal for a wide range of applications.

One of the key factors driving the growth of engineering plastic production is the increasing focus on sustainability and environmental friendliness. Unlike traditional plastics, engineering plastics are known for their durability and resistance to heat, chemicals, and impact. This makes them a more sustainable option for manufacturers looking to reduce their environmental footprint.

Furthermore, the versatility of engineering plastics allows for greater innovation and design flexibility in product development. With properties such as high strength-to-weight ratio, dimensional stability, and excellent machinability, engineering plastics offer endless possibilities for engineers and designers to create new and improved products.

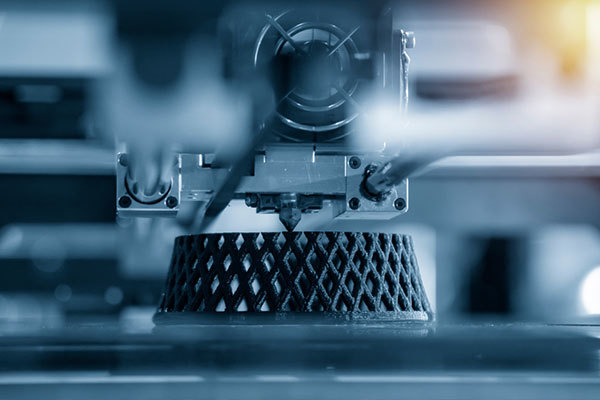

As the demand for engineering plastics continues to grow, manufacturers are investing in new technologies and processes to meet the needs of their customers. Advanced injection molding techniques, additive manufacturing, and compounding methods are being utilized to produce high-quality engineering plastics with enhanced properties and performance.

In conclusion, the production of engineering plastics is experiencing rapid growth due to their unique properties, sustainability benefits, and versatility in various industries. With continued advancements in technology and innovation, the future of engineering plastic production looks promising, paving the way for a more sustainable and efficient manufacturing industry.