The future development trend of engineering plastics

Time:

Nov 12,2024

In recent years, engineering plastics have played an increasingly important role in various industries due to their superior mechanical, thermal, and chemical properties.

In recent years, engineering plastics have played an increasingly important role in various industries due to their superior mechanical, thermal, and chemical properties. As technology continues to advance, the future development trend of engineering plastics is expected to focus on the following key areas.

Firstly, there is a growing demand for engineering plastics with enhanced sustainability and environmental friendliness. With increasing concerns about climate change and environmental pollution, manufacturers are seeking alternative materials that have a lower carbon footprint and can be easily recycled or biodegraded. In response to this demand, researchers and engineers are developing new engineering plastics derived from renewable resources such as bio-based polymers or recycled plastics.

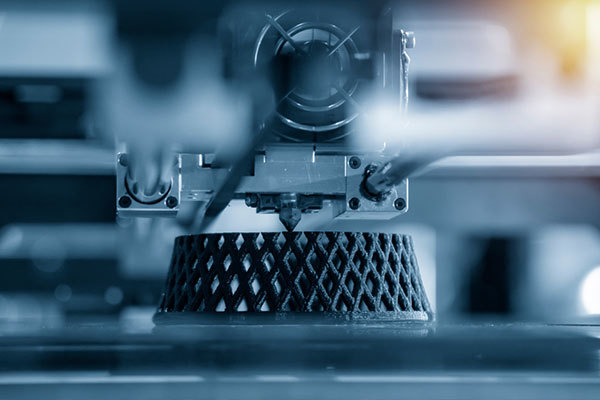

Secondly, there is a trend towards the development of engineering plastics with improved performance and functionality. As industries become more competitive, there is a need for materials that can withstand harsher operating conditions, have higher strength and stiffness, or possess special properties such as self-healing or shape memory. To meet these requirements, scientists are exploring new polymer blends, nanocomposites, and additive manufacturing techniques to create innovative engineering plastics with superior performance characteristics.

Furthermore, the digitalization of manufacturing processes is driving the development of smart engineering plastics that can sense and respond to external stimuli. By incorporating sensors, actuators, and electronics into the polymer matrix, engineers are creating materials that can monitor their own condition, adapt to changing environments, or even repair themselves autonomously. These smart engineering plastics have the potential to revolutionize industries such as automotive, aerospace, and electronics by enabling the production of self-monitoring and self-healing components.

In conclusion, the future of engineering plastics is bright and full of opportunities for innovation and advancement. By focusing on sustainability, performance enhancement, and smart functionality, researchers and engineers are paving the way for the development of next-generation materials that will shape the industries of tomorrow. As we continue to push the boundaries of material science and engineering, the possibilities for engineering plastics are truly endless.